MW1630 - Moflon Large Current Slip Ring

OD 30mm * Length 66mm, 6Wires * 30A

MW1630 slip rings are small and compact with OD 30.00mm * L 66mm, standard, off-the-shelf.Color-coded lead wires are used on both the stator and rotor for simplified electrical connections. Using a 90° V-groove ring design for each ring.

- If you don't see what you want in this website,let us know; we may already have it designed or we will modify a design to meet your requirements. In many cases the specifications in the catalog can be changed to include bore size, circuits number, higher current/voltage,flange, lead wire length,shielding,connectors,higher speed,IP68,military grade,higher temperature, mixed with pneumatic/hydraulic capability. Please ask if you don't see exactly what you need as only a small fraction of our Moflon slip rings are included in this catalog!

- MW16309 is the high-end version corresponding to MW1630.

- Optional flange mounting.

- Specified connectors and Heat-shrink tube.

- Longer lead lengths available.

- High temperature is optional.

- Military Grade.

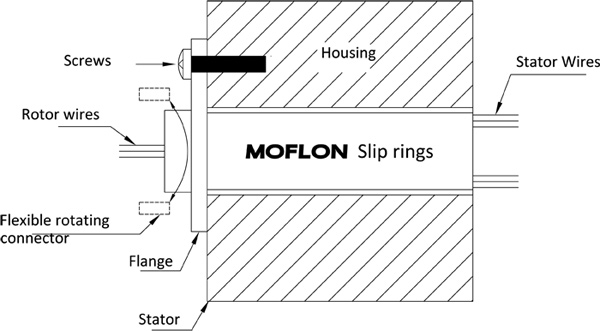

Flange Mounting Instructions

1. Align the mounting holes in the flange to mounting base and install flat washers and thread forming screws (NOT SUPPLIED) for plastic. Securely tighten screws.

2. Route the wiring and make the necessary connections. Do not allow the wiring to restrict free rotation of the slip ring.

3. Position a screw or dowel (NOT SUPPLIED) in the anti-rotation tab to the dimension as shown.

CAUTION: Because of possible geometric mismatching between the customer��s application and the slip ring, 'hard mounting' of both ends of the slip ring (i.e., securing the rotor and stator such that there is NO floating during operation) is not recommended and may cause premature failure

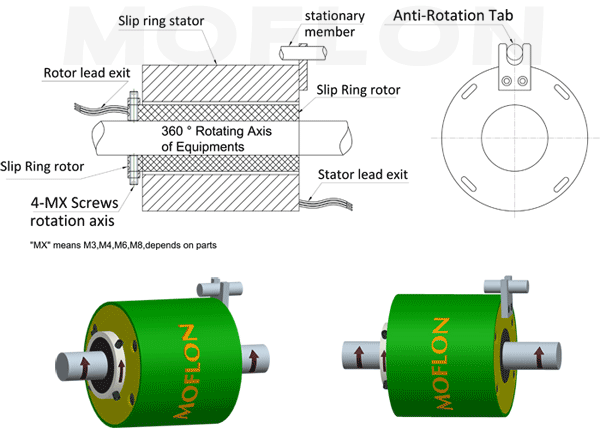

Shaft Mounting Instructions(For Through bore style)

1.Main shaft mouted units:

A.Position the slip ring in the desired location and tighten both set screws to the shaft.Maximum torque 25Ib-in(DO NOT OVER TORQUE)

B.Route the wiring and make the neccessary connections.Do not allow the wiring to restrict free rotation of the slip ring.Do not constrain wiring such that wire flexing occurs.Doing so will ultimately cause failure(breakage of the wiring).

2.Housing mouted units:

A.Anti-Rotation tap used for connecting the stator of slip ring with the stationary member of euipment

B.Route the wiring and make the neccessary connections.Do not allow the wiring to restrict free rotation of the slip ring.

Typical Application

- Small wind turbine.

- Automation.

- Cut equipments.

- Rotary table

- Robotics

- Laboratory equipmen

- Manufacturing and process control equipment