MB120 - Geniş Bant Slip Rings

MB500 slip ringler, 12.7mm(0.5") iç çaplı, 56mm dış çaplı olup, özel slip ring çözümleridir, gücü, sinyal, Ethernet, USB, Devicenet, Control Net, Canbus ile talep üzerine kombine edebilir! Şaft veya opsiyonel flanş montajı işle bağlanabilir.

MB120 serisi yüksek hızda veriyi aşağıdaki gibi iletebilir:

• 232 485 422 protocol

• Profibus,CAN-Bus, LonWorks,Device Net,Control Net,Profinet

• EtherCAT、Interbus、Modbus ve daha birçoğu.

• Ethernet (10M / 100M / 1000M BaseT).

• USB 1.0,USB2.0

• Video

| Shared Specifications |

| Circuits |

depends on your request |

Current |

Signal(2A) or 10A |

| Voltage |

250 VDC/VAC |

Max speed |

600RPM |

| Through bore size |

12.7mm(1/2") |

Overall diameter |

56mm(2.2") |

| Housing Material |

Aluminium Alloy |

Torque |

0.8N.m |

| Working life |

depends on working speed |

Contact material |

Precious Metal:Gold-Gold |

| Electrical noise |

<10 milliohms |

Contact Resistance |

<100mOhm(AWG16#,300mm) |

| Dielectric strength |

800VDC@50Hz |

Lead Wire |

UL Teflon® |

| Insulation resistance |

1000MΩ@600VDC |

Lead Lengths |

250mm |

| Operating Temp. |

-40°C to 80°C |

Protection |

IP51 |

| Mechanical vibratio |

MIL-SID-810E |

Humidity |

10% to 90% RH |

| Materials |

Lead Free,RoHS compliant |

CE Certified |

YES |

|

*Please note: 10A rings parallel can be used as multiple 10A large current.

For Example: 3 rings parallel = 1 wires 30A, please see order instructions

1)The operational life of the unit is dependent upon rotational speed, environment and temperature.

2)Lead Wire size: 2A/signal -> AWG22, 10A -> AWG16, 20A -> Awg14, colored code.

3)Electrical noise is dependent upon the rotating speed and current,voltage.

|

| How to Order? |

Please see ordering information instructions as below:

MB120

- Broadband Type:

- F - 10, 100 BaseT Ethernet - RJ45

- E - 1000 BaseT Ethernet - RJ45

- P - Profibus - 9-Pin D-Sub

- C - CanBus - 9-Pin D-Sub

- D - Device Net - 5 Pin Micro Change

- T - Control Net - 75 Ω BNC

- V - USB 1.0

- U - USB 2.0

- Q - Coax - 75 Ω BNC

Build-On-Request Flowing:

|

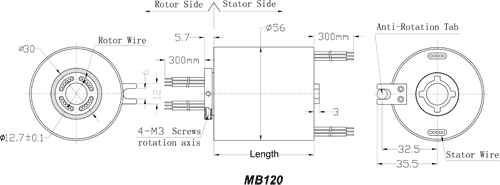

Standard drawings:

12 wires for one group color. from 13 ... 24, repeat the same color as 1 ... 12,indicated with number code pipe.

| Lead wire Color codes |

| Rings# |

Color Code |

Rings# |

Color Code |

Rings# |

Color Code |

| 1 |

BLK |

5 |

YEL |

9 |

GRY |

| 2 |

BRN |

6 |

GRN |

10 |

WHT |

| 3 |

RED |

7 |

BLU |

11 |

PINK |

| 4 |

ORN |

8 |

PURPLE |

12 |

AZURY |

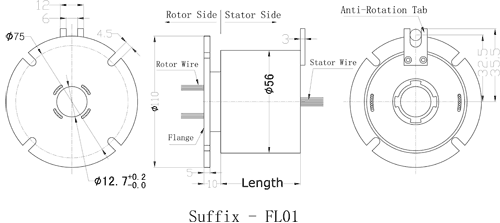

Optional Flanges mounting:

At sometimes, we need a different flange for mounting instead, how should we do?

Great! Moflon supply flange style as below:

(when you order, pls add FL01 at the suffix of Part#, for example: MB120-06S-FL01 means MB120-06S with optional flange FL01.)

- If you don't see what you want in this website,let us know; we may already have it designed or we will modify a design to meet your requirements. In many cases the specifications in the catalog can be changed to include bore size, circuits number, higher current/voltage,flange, lead wire length,shielding,connectors,higher speed,IP68,military grade,higher temperature, mixed with pneumatic/hydraulic capability. Please ask if you don't see exactly what you need as only a small fraction of our Moflon slip rings are included in this catalog!

-

- Can combine more wires:1-96Ring

- Specified connectors and Heat-shrink tube.

- Longer lead lengths available.

- Shielded cables

- Connectors

- Frequencies up to 500 MHz

- High-speed data transmission for fast Ethernet and EtherCat

- Signal, Coax, and Power combinations

- Thermocouples

- Shock, Vibration, and Temperature Qualified

- Pneumatic/Hydraulic Capability

- High temperature---up to 450 degree

- High Voltage & large Current(1000A)

- Military Grade.

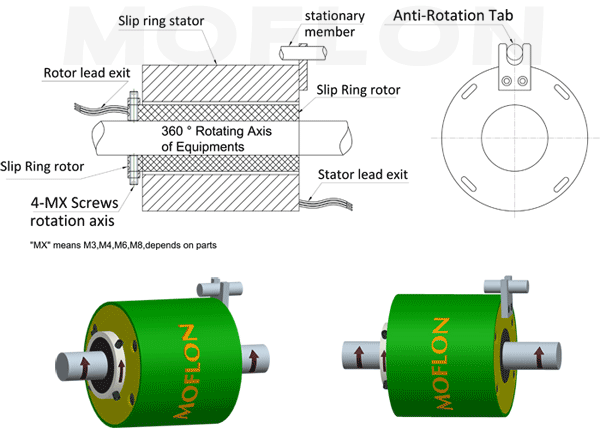

1.Main shaft mouted units:

A.Position the slip ring in the desired location and tighten both set screws to the shaft.Maximum torque 25Ib-in(DO NOT OVER TORQUE)

B.Route the wiring and make the neccessary connections.Do not allow the wiring to restrict free rotation of the slip ring.Do not constrain wiring such that wire flexing occurs.Doing so will ultimately cause failure(breakage of the wiring).

2.Housing mouted units:

A.Anti-Rotation tap used for connecting the stator of slip ring with the stationary member of euipment

B.Route the wiring and make the neccessary connections.Do not allow the wiring to restrict free rotation of the slip ring.

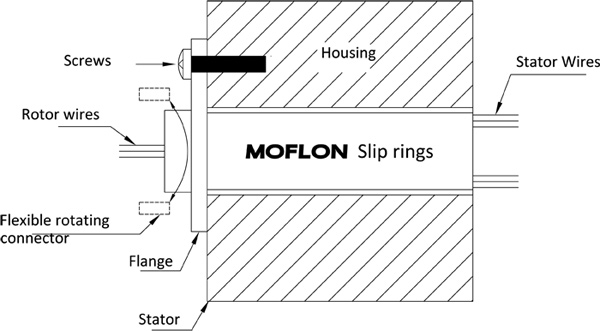

Flange Mounting Instructions

1. Align the mounting holes in the flange to mounting base and install flat washers and thread forming screws (NOT SUPPLIED) for plastic. Securely tighten screws.

2. Route the wiring and make the necessary connections. Do not allow the wiring to restrict free rotation of the slip ring.

3. Position a screw or dowel (NOT SUPPLIED) in the anti-rotation tab to the dimension as shown.

CAUTION: Because of possible geometric mismatching between the customer��s application and the slip ring, 'hard mounting' of both ends of the slip ring (i.e., securing the rotor and stator such that there is NO floating during operation) is not recommended and may cause premature failure

Typical Application

- Industrial machinery

- Filling equipment

- Exhibit / display equipment

- Medical equipment

- machining centerse

- rotary index tables

- Mechanical arm

- Surgery lamp

- heavy equipment turrets or cable reels

- Revolving door

- Packaging machine

- Coiling machine

- test equipment

- packaging machines